Custom Fields can be created for any of Assembly Planner's entities. Custom fields allow clients to track information beyond the standard fields included in Assembly Planner.

Types of entities and custom field examples

•Item custom fields track a property of a part that is universal to that item, regardless of the operation or activity being performed. For example, the supplier of a certain type of bolt or the material cost for a part are custom fields that could be created.

•BOMItem custom fields are different than Item custom fields. BOMItem does not refer to the item universally, but to the item under a specific parent. The quantity of legs used to assemble a chair is a BOMItem, because the number of required legs is specific to the parent chair and is not an item-specific piece of information. Possible custom fields may be PartLocation (Where is this part being stored on the line under this particular BOM?) or OperationSequenceNumber (Which task uses this part?).

•Routing custom fields track information about processes beyond the standard information that Assembly Planner asks for. For example, suppose that the engineers at MyPlant know that they would outsource the assembly chair legs to PlantX if cost-cutting measures dictated and union rules allowed. A custom field could be created to track the OutsourceVendor.

•Operation custom fields describe information about workstations. AlternateWorkstation would be a good custom field when work may need to be transferred quickly from the regular station.

•Activity custom fields describe tasks being done by an operator. Whether or not the activity requires a SafetyFlag would be easy to track with a custom field.

•Consumption LineLocation or TorqueSetting

•Resource custom field examples are plentiful: Cost, Vendor or MaintenanceSchedule are all things that may be interesting to users.

•ProcessResourceMapping custom fields describe the relationship of a resource with a specific process. Sample fields include TorqueSetting or Quantity. Some process may require a higher torque setting on a resource than a different process using the same resource.

•ProcessStructure custom fields are created to track something interesting about a particular activity under a particular process, where the property being tracked is not universal to that activity. Perhaps an activity like tightening a bolt normally does not require the operator to wear gloves, but there is one particular process where the bolt-tightening activity does require gloves. A RequiredPPE custom field could record this.

•Workstation custom fields record data about specific workstations. Perhaps the Overhead or LaborCost for workstations need to be included in Assembly Planner.

•Plant custom fields deal with information related to stations or the entire plant. For example, SquareFootage or YearBuilt.

•Model custom fields can be used to describe families, special characteristics, etc.

•Option custom fields can be used to describe families, special characteristics, etc.

•ProcessStructureOptionMapping2 custom fields can be used to capture properties of option mapping in the Activity Model/Option mapping tab.

•ControlPlanDetails custom fields can be used to capture data included in Control Plans.

•MCO custom fields can be used to store details captured on an MCO

•Location custom fields can be used to describe locations defined in PFEP.

•RackLocation custom fields can be used to describe racks defined in PFEP.

•ItemRackLocationMapping custom fields can be used to describe and detail part plans defined in PFEP.

•KanbanCard custom fields are controlled by Proplanner at this time and cannot be viewed or edited.

•Cart custom fields can be used to describe kitting carts defined in PFEP.

•CartType custom fields can be used to describe kitting cart types defined in PFEP.

•ScanningGroup custom fields can be used to describe cart groups defined in PFEP.

•Container custom fields can be used to describe kanban containers defined in PFEP.

•ContainerClass custom fields can be used to describe kanban container classes defined in PFEP.

•ContainerType custom fields can be used to describe kanban container types defined in PFEP.

•ReplenishmentSystem custom fields can be used to describe replenishment systems defined in PFEP.

•OutputMethod custom fields can be used to describe output methods defined in PFEP.

•Supplier custom fields can be used to describe suppliers defined in PFEP.

•SupplierItemMapping custom fields can be used to store relevant properties of items delivered or managed by particular suppliers in PFEP.

•WorkSteps custom fields can be used to provide details associated with work steps.

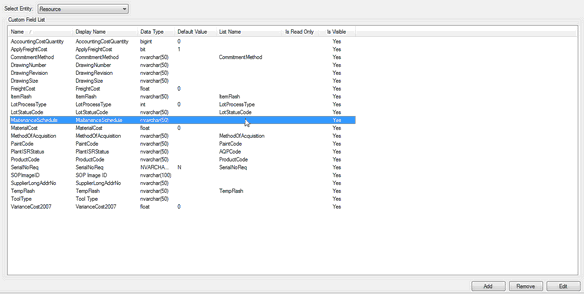

A snapshot of the custom fields manager is shown below. The custom fields manager allows you to add, remove and edit custom fields.

The first thing you must do is use the "Select Entity" drop-down to select the type of custom field you would like to view, create, or edit.

Find Desired Field

Add Custom Fields Function

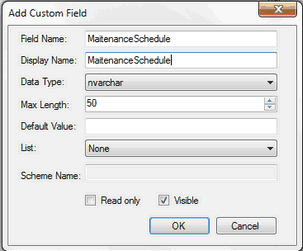

After you have selected the entity, you can click on the 'Add' button in the bottom right hand corner of the window and fill out the information shown below.

Add Custom Field

The Field Name is the name that will be used to store the associated information in the database. There should not be any spaces or special characters in the Field Name. The Display Name is what will be shown in Assembly Planner; it may include spaces but is best if it is similar to the Field Name.

Data Type is a drop-down where you specify the information the field will contain.

•nvarchar is for text entry.

•bit is for "yes or no" (Boolean) questions. Choosing bit will create checkboxes in the new custom field.

•int (integer) is for numeric data (whole numbers).

•bigint is essentially the same as int but is for very large values (greater than 2.15 billion).

•float is for numeric data requiring decimal entry.

•datetime formats the field entry as a date and time.

Max Length allows you to specify the maximum length the field entry can be (typically used for the nvarchar data type).

Default Value, if specified, will automatically fill in the field with this value unless you choose to enter a different value. If there is a list defined for this field then the default should be an entry from that list. For example, perhaps freight cost is only something that needs to be tracked on 1 in 1000 parts, and for the other 999, freight cost is negligible. Entering a default value of 0 will automatically take care of the freight cost field for the 999 parts that are not of interest.

List provides a drop-down menu where you can choose to associate a list with the custom field. The effect is that you will see a drop-down menu to choose from when entering information in the custom field. The list can be chosen from those provided with Assembly Planner, or a new one can be created in with the List Management tool in Data Management. Note: In order for a list to appear for a newly created custom field, you must restart Assembly Planner.

If there is not a list associated with it, the field is open for you to enter information as you see fit. If the administrator wants to control what is entered, a list needs to be associated with the custom field. For example, it may be important to have a list in a situation where information for an MRP system is going to be extracted from Assembly Planner. This would restrict the users to information that is correct and usable by the MRP system. However, a list would typically not be appropriate for something like the description of activities on an assembly line. In this case, it would be important to give users the freedom to enter information without a list.

The two check boxes at the bottom of the window allow the administrator to specify the type of information contained in the custom field. If the Read only box is checked, administrators will be able to edit the fields, but other users will only be able to see the field. If it is not checked, the users will be able to modify information in the field. If the Visible box is checked, the field will not be visible to non-administrator users. This would work well for information that the administrator needs to use, but that would confuse other users. For example, it may be helpful for an administrator to create a custom field tracing the work centers where operations currently take place. Then after completing a line balance, the administrator will be able to report which operations have moved and which remain at the same work center. However, it would not be necessary for other Assembly Planner users to view the current work center field.

For further instruction on Creating Custom Fields, Creating Lists for custom fields, and Associating those lists with the correct Custom Field, see the appropriate section of the Quick Start Tutorial.