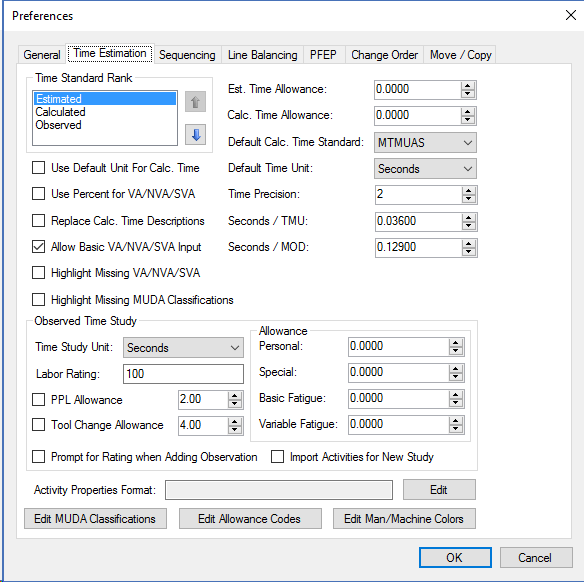

You can set the default preferences for Time Estimation in this window. These preferences mostly affect time studies. The Time Standard Rank, however, also affects the Line Balance module and any report that rolls up times.

Time Estimation Tab

Time Std Rank: The time standard rank sets the order in which the types of task times are used (for generating Reports, for example). You can associate three different types of times to tasks: observed times, calculated times, and estimated times. Some tasks may have all three types recorded while other tasks only have one recorded.

If you choose Calculated-Estimated-Observed as your ranking, Assembly Planner will look for a calculated time for each task first. If there is a calculated time recorded, that time will be used. If there is no calculated time recorded, Assembly Planner moves to the second standard on the list and looks for an Estimated time. Assembly Planner works this way for any ranking. It looks first for your first choice ranking, and if that is absent, it moves to the second choice, and finally to the third choice. This happens on a task-by-task basis, so when Assembly Planner is rolling up (adding up) several tasks to find an operation time, it is possible some calculated times will be added to some estimated and observed times, depending on how the tasks' times were recorded.

Est Time Allowance: The estimated time allowance is a percent allowance added to estimated times. If the allowance is set to 10.0, for example, an activity with a time of 30 seconds would have a 3 second allowance added.

Calc Time Allowance: The calculated time allowance is a percent allowance added to all calculated times associated with an activity.

Default Calc. Time Standard allows you to set a default system for predetermined time studies. Assembly Planner provides several popular systems.

•MTM1 is the Methods-Time Measurement system

•MTMB, a derivative of MTM1, was designed for longer, less repetitive processes.

•MTMUAS was designed for batch production. It was created based on MTM1.

•MODAPTS is popular in industries like healthcare and automotive.

•BMOST contains Basic assembly, as well as General, Tooling, Equipment, and Crane elements.

•STDS is a company-specific standard.

Default Time Unit: Default Time Unit specifies the unit that will be used throughout Assembly Planner. Choices include Minutes, Hours, Days, TMUs (Time Measurement Units—1 TMU=0.00001 hour=0.036 seconds), MUs (Measurement Units—1 MU=0.1 TMU), MOD (MODAPTS Time Units—1 MOD=0.129 seconds) or TWTMIN (Task Weighted Time in minutes). Note: Set this preference before starting a new time study. If you change this setting and open an existing study, the time unit for that study will not change.

Default conversion between time units:

TO CONVERT FROM: |

TO MICROSECONDS, MULTIPLY BY |

TO SECONDS, MULTIPLY BY |

TO MINUTES, MULTIPLY BY |

Microseconds |

1.0000 |

0.000001 |

1.66667E-08 |

Seconds |

1000000.0000 |

1.00000 |

0.01667 |

Minutes |

60000000.0000 |

60.00000 |

1.00000 |

Hours |

3600000000.0000 |

3600.00000 |

60.00000 |

Days |

86400000000.0000 |

86400.00000 |

1440.00000 |

TMUs |

36000.0000 |

0.03600 |

0.00060 |

MUs |

3600.0000 |

0.00360 |

0.00006 |

MODs |

129032.2580 |

0.12903 |

0.00215 |

TWTMINs |

70796460.1770 |

70.79646 |

1.17994 |

Use Default Time Unit for Calc Time: If the box for "Use Default Time for Calc Time" is checked, Assembly Planner will display calculated times in the default time unit instead of TMUs.

Use Percent for VA/NVA/SVA: When this box is left unchecked, you will enter time values in the VA/NVA/SVA columns. When this box is checked, you can enter percentage values to represent the portions of the task that are VA/NVA/SVA.

Replace Calc. Time Descriptions: This sets your preference for how existing rows in calculated time studies are updated when the time standard templates are updated. If the time standard templates are modified and this box is checked, then all elements of existing calculated time studies will be updated whenever the element code in the template (including the description) is changed. If the box is unchecked when the element in the template is modified, the time for that element will be updated in any existing time studies, but the descriptions in the time studies will not be updated--the old descriptions will remain.

Time Precision: Time Precision specifies the number of places after the decimal point in times. For example, if Time Precision is set to three and the time units are seconds, an activity's time could be displayed as 32.256 seconds.

Seconds/TMU: This sets the conversion factor for 1 unit (TMU) to seconds. The default is 1 TMU = 0.036 seconds.

Seconds/MOD: This sets the conversion factor for 1 unit (MOD) to seconds. The default is 1 MOD = 0.129 seconds.

Observed Time Study - Time Study Unit: Time Study Unit specifies the unit used for observed time studies. (This may be different from Default Time Unit).

Observed Time Study - Study Type: Study Type allows you to choose which observed time method will be the default method for use in the study.

•Video studies are performed via a pre-recorded digital video with times recorded on two integrated spreadsheets. The elements of the tasks can be entered in the Tasks spreadsheet prior to performing the time study. Perform the time study by observing when the elements occur and using the play, pause, record, and stop controls to capture times, recording the times in the Observations spreadsheet.

•Real Time studies provide two integrated spreadsheets and a stopwatch. The elements of the tasks can be entered in the Tasks spreadsheet prior to performing the time study. Perform the time study by observing when the elements occur and using the play, pause, record, and stop controls to capture times, recording the times in the Observations spreadsheet.

Observed Time Study - Labor Rating: The Labor Rating is the default performance rating given to newly created operators. This rating affects the normal time calculation in observed time studies.

Observed Time Study - Prompt For Rating when Adding Observations: If this box is checked, after every observation, a window will appear, prompting you to adjust the performance rating for that observation.

Observed Time Study - Import Activities for New Study: If this box is checked, an "Import Activities" right-click menu option will appear in the Tasks Table of a study, allowing you to add activities that already exist in the Assembly Planner database.

Observed Time Study - Allowances: (PF&D allowances) are used in Observed Time studies. The following four settings populate the default values shown in the Observed Time > Settings Tab.

•Personal

•Special

•Basic Fatigue

•Variable Fatigue

PPL Allowance: You can choose to enable or disable this allowance. When the PPL allowance is enabled, you can define the default allowance applied to the tasks. The default value represents a percentage applied and added to each activity's time in the observed time study, allowing time for cleaning a work station or area.

Note: This allowance is only used in the Observed Time Study tool within the Activity Time tab.

Tool Change Allowance: You can choose to enable or disable this allowance. When the tool change allowance is enabled, you can define the default allowance applied to the tasks. The default value represents a percentage applied and added to each activity's time in an observed time study, allowing time to change tools between tasks.

Note: This allowance is only used in the Observed Time Study tool within the Activity Time tab

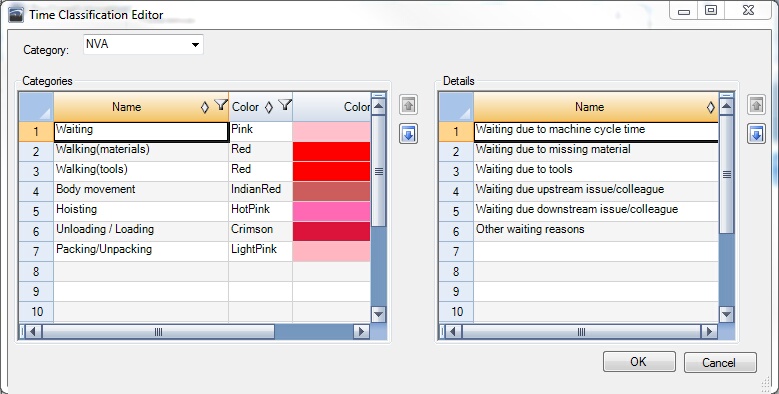

Edit MUDA Classifications: Assembly Planner allows you to not only define tasks as value-added, non value-added, or semi value-added (or a combination thereof), but also to define specific categories within each of those classifications. Default VA/NVA/SVA category sets are provided in Assembly Planner, but you can edit and add categories by selecting the Edit MUDA Classifications button.

Select the category you wish to edit, and enter/edit the Category names and colors associated to each category. You can break down each category further by entering a list of Details. In the example below, There are six different types of work that would be categorized into Waiting, which is defined as non value-added.

If you only wish to define categories, but not the details within each category, a default detail will be set to match each category.

Edit MUDA Classifications Window to Edit VA/NVA/SVA Categories and Details

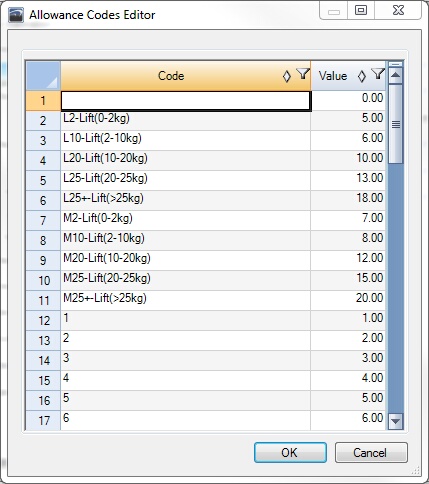

Edit Allowance Codes: To edit the allowance codes for Observed Time studies, click on the "Edit Allowance Codes" button. In Assembly Planner, you can set personal, fatigue, and special allowances for all tasks in a study, and you can also assign allowances to individual tasks. This may apply in cases of heavy lifting or moving, for example. There are default values set, but you can edit allowance codes and their values to fit your needs.

Simply edit the spreadsheet and click OK. You will be warned that you will need to restart the application before the changes will take effect.

Edit Allowance Codes Window to set default allowances that can be applied to individual tasks

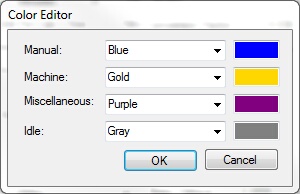

Edit Man/Machine Colors: You can also edit the colors representing each type of task in the Man/Machine Utilization Report. Click on the Edit Man/Machine Colors button to get to the window shown below. Select the colors you wish to be displayed for each task type.

Edit Man/Machine Colors Window