A Control Plan is a description of the characteristics, measurements, and evaluation and control methods for each part or process during a phase of manufacturing. A Control Plan serves as a living document that helps mitigate or reduce potential failures identified in the Failure Modes and Effects Analysis (FMEA). In Assembly Planner, Control Plans can be developed for activities, operations, and routings.

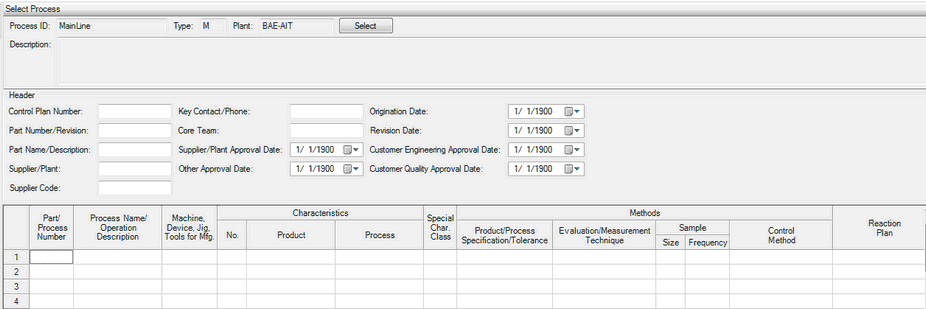

To begin creating or editing a Control Plan, first Check Out the process you wish to edit in the Assembly Planner Library. Then select the appropriate activity, operation, or routing in the Control Plan Module by clicking the Select button. Then click the Edit button at the bottom right hand corner of the screen. From there, header details can be filled in and the spreadsheet can be used to develop the plan. The header details include Control Plan Number, Key Contact/Phone Number, and Core Team as seen in the figure below.

Control Plan Sheet View

The Control Plan spreadsheet follows a standard Control Plan format. Enter in the information pertinent to the Control Plan, this information usually includes the critical inputs or key outputs for a process. Data can be typed in or copied in from another application such as Excel. If copied from Excel, make sure the columns in your file are in the same order as the columns in the Control Plan module spreadsheet. After the Control Plan has been created, make sure to click Save when you are finished. Once a Control Plan is saved for an activity, operation, or routing, that Control Plan can always be accessed by returning to the Control Plan Module and selecting that activity, operation, or routing.

Certain details can be pulled into a Control Plan from other Assembly Planner modules, as listed in the table below.

Other Module Data/Field |

Control Plan Field |

Activity Resource tab |

Machine, Device, Jig, Tools for Mfg. |

FMEA Function |

Process Name/Operation Description |

FMEA Requirement |

Product/Process/Specification/Tolerance |

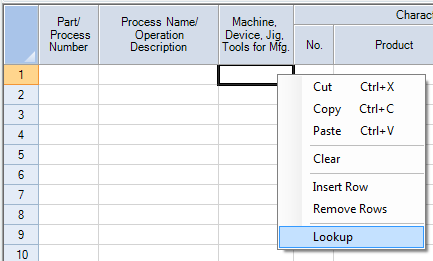

Machine, Device, Jig, Tools for Mfg.

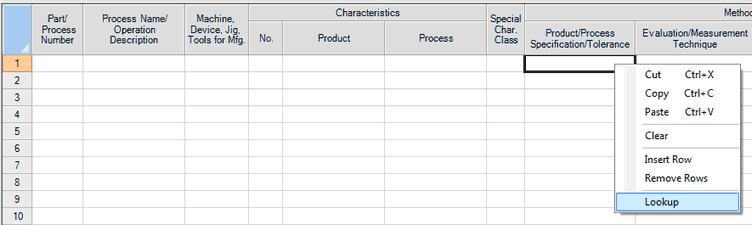

If you have mapped resources to activities, you can populate the Control Plan's Machine, Device, Jig, Tools for Mfg. field with those same resources. To do this, right click on the Machine, Device, Jig, Tools for Mfg. field (make sure you're in edit mode), and select 'Lookup' from the menu.

Note: If you have selected an activity, you will see all resources mapped to that activity. If you have selected an operation, you will see all resources mapped to all activities in that operation. If you have selected a routing, you will see all resources mapped to all activities in that routing.

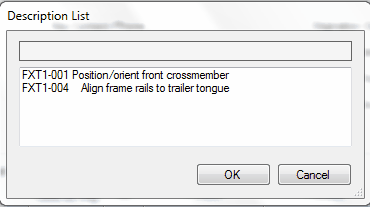

Control Plan Machine Lookup

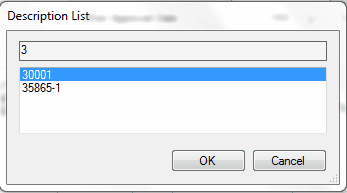

Description List

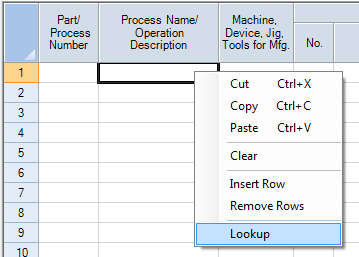

Process Name/Operation Description

The Process Name/Operation Description associates with the Function column in the FMEA. If you have completed an FMEA for the selected process, you can populate the Control Plan's Process Name/Operation Description with entries made in the FMEA's Function field. If you have recently made updates, make sure to save and refresh your search for the control plan to have the Lookup table populate correctly. To do this, right click on the Process Name/Operation Description field (make sure you're in edit mode), and select 'Lookup' from the menu.

Note: You will only see entries made for the selected process's corresponding FMEA.

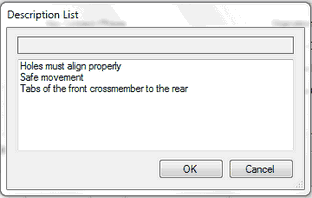

Lookup Process Name/Opereation and Description

Description List

Product/Process/Specification/Tolerance

The Product/Process/Specification/Tolerance associates with the Requirement column in the FMEA. If you have completed an FMEA for the selected process, you can populate the Control Plan's Product/Process/Specification/Tolerance with entries made in the FMEA's Requirement field. If you have recently made updates, make sure to save and refresh your search for the control plan to have the Lookup table populate correctly. To do this, right click on the Product/Process/Specification/Tolerance field (make sure you're in edit mode), and select 'Lookup' from the menu.

Note: You will only see entries made for the selected process's corresponding FMEA.

Lookup Product/Process

Description List