|

The Supermarket Picklist screen is the entry point for all of the Just-In-Sequence Part Kitting functionality. The user may select the appropriate supermarket from a drop-down list, and then move to Open Cart, Close Cart or Deliver Cart.

|

|

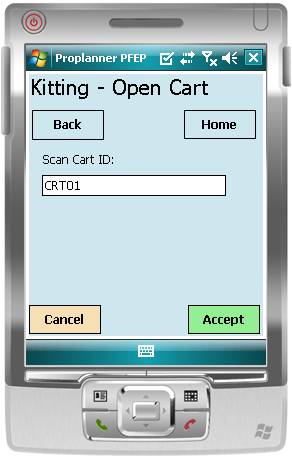

The Open Cart screen allows the user to scan the barcode or enter the ID of the cart for which parts are being picked. |

|

The Kit Info screen prompts the user to pick parts and load them in the cart. As parts are picked, the location ID should be scanned. This will mark the parts as 'picked'. Scan or enter the location for the part ID displayed to indicate that it has been picked. The 'Skip' button should only be used if a part is not available to be loaded in the kit. |

|

If the 'Skip' button is selected, enter the shortage quantity and click 'Yes.' You will be returned to the Kit Info screen. |

|

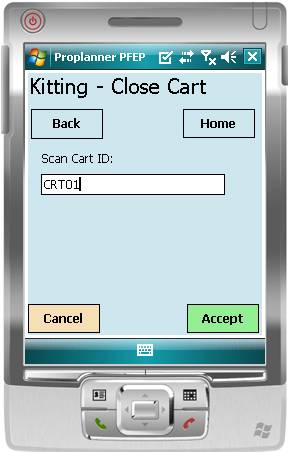

When all of the parts have been picked, scan or enter the cart ID in the Close Cart screen. This will log that the kit has been completed.

|

|

When you are back to the Supermarket Picklist, you can choose to generate and open a Cart Group. A Cart Group is one or more carts that can be tracked and scanned together during transit. Click on 'Groups' to open a Cart Group. |

|

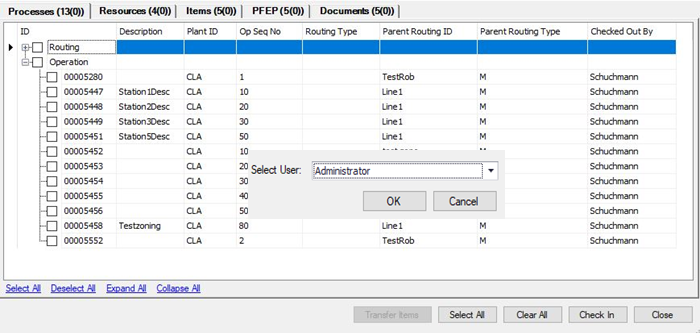

On the Kitting Group Mgmt screen you can choose to 'Open Group,' which allows you to identify a new cart group ID (which may already be defined in the Groups tab of the PFEP Containers Editor. You can 'Add To Group,' which allows you to add cart IDs to cart groups. You can also 'Remove From Group,' which allows you to separate a Cart ID from a Group.

|

|

The last button on the Kitting Group Mgmt screen is 'Close Group.' Here you can scan the location to which the entire cart group has been delivered. This creates a transit scan for all the child carts in the group to this location. |

|

If you are on the Supermarket Picklist screen, you will also see an option to perform a Transit Scan. On this screen you will scan the location of the cart, and scan the Cart or Cart Group ID. This enables tracking of the carts when it is en route to its delivery location. |

|

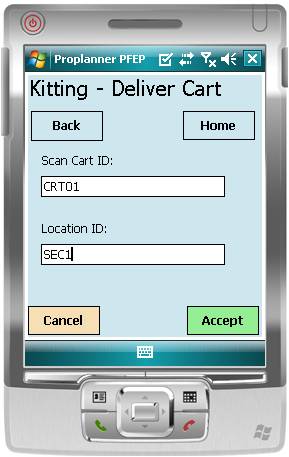

The Deliver Cart screen allows the material handler who delivers the cart to scan the cart ID and enter the location ID, which will mark the cart as delivered. Note that a cart cannot be re-opened unless it is in the delivered state. That is, you will not be able to re-load a cart until the system has a record of the previous load being delivered. |

The Supermarket Picklist work flow for a material handler is as follows:

1.Scan the cart barcode.

2.The cart has a fixed number of units that will have kits loaded. For the appropriate number of units, the serial number(s) will be displayed on the screen. These serial numbers will be the next units in the build list, for the sector to which the kit is assigned.

3.Parts to be picked for the units will be displayed.

4.For each part picked, scan the location/rack.

5.When all parts have been picked, close the cart by scanning the cart barcode again.

6.Scan the next cart's barcode.