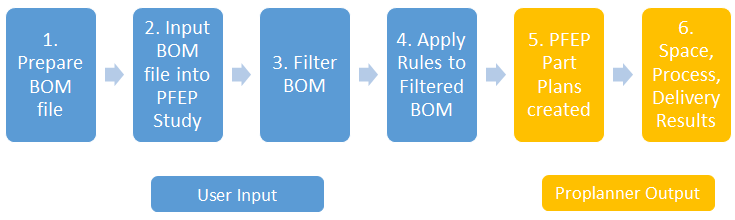

Process Overview:

1.Prepare the BOM File:

The following column names, marked as required or optional, should be in the first row of the BOM Excel file:

Column Name (must match exactly) |

Required |

Data Type in Column |

Component |

Yes |

Cannot be null or empty |

Item Text |

No |

May be a null or empty string |

UsageType |

No |

May be a null or empty string |

From Location |

Yes |

Cannot be null or empty |

To Location |

Yes |

Cannot be null or empty |

Parent |

No |

May be a null or empty string |

Vehicle Program |

No |

May be a null or empty string |

Primary Packaging Container |

No |

May be a null or empty string |

PrimaryContainer2 |

No |

May be a null or empty string |

Max Qty Per Container |

No |

May be null, empty or numeric |

Secondary Packaging Container |

No |

May be a null or empty string |

Secondary Packaging Quantity per Unit Load |

No |

May be null, empty or numeric |

DOHInventory |

No |

May be null, empty or numeric |

Option Code Take Rate |

No |

May be null, empty or numeric |

PPV |

No |

May be null, empty or numeric |

Classification |

No |

May be a null or empty string |

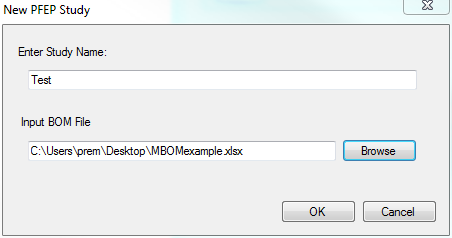

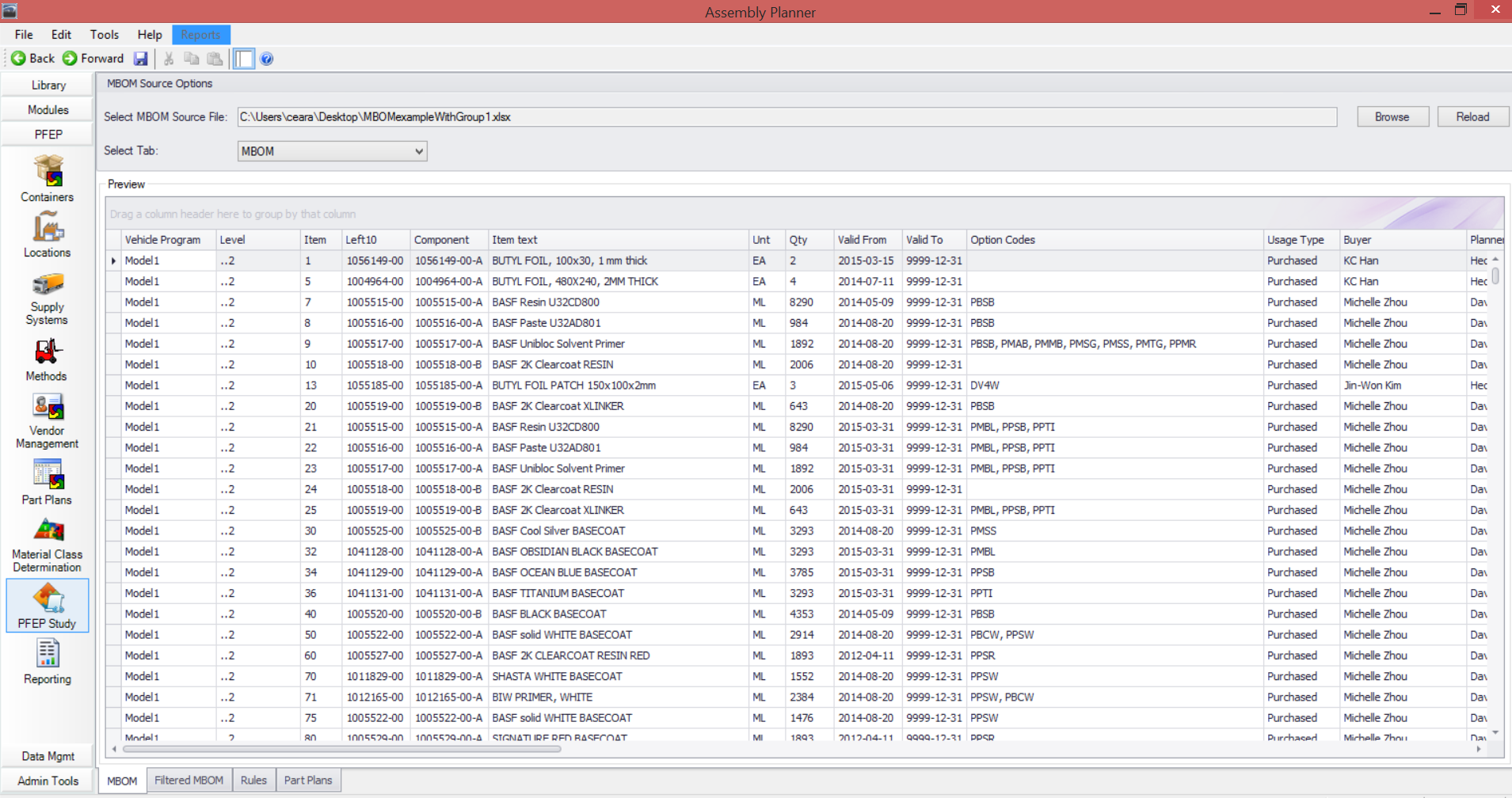

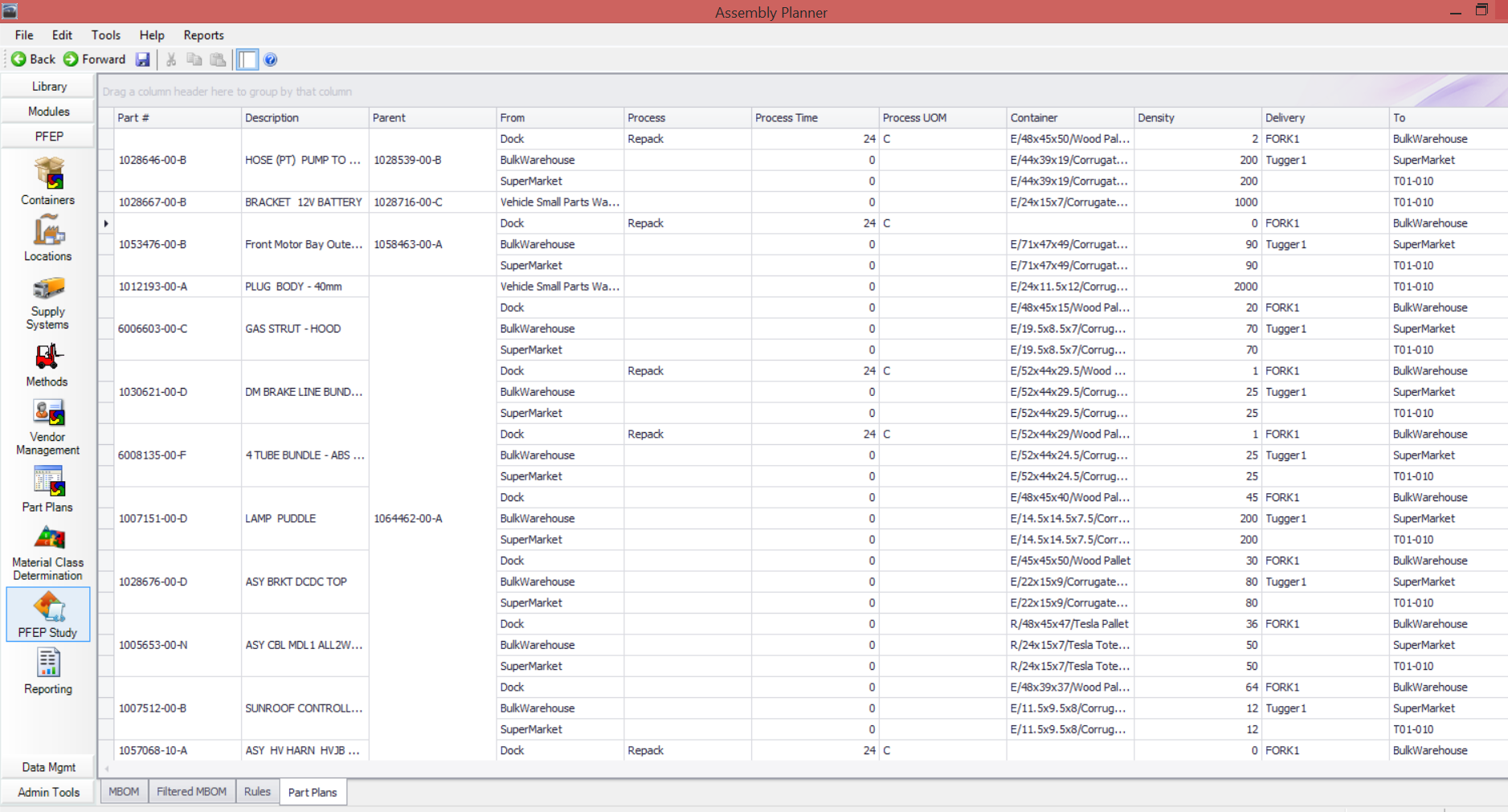

2.Input BOM File into PFEP Study tool:

1.In the PFEP module, click the PFEP Study icon.

2.To start a new PFEP study, click on the Create New Study icon.

a.Type a Study Name in the appropriate box.

b.Browse to and select a BOM file. Click OK.

c.Review the MBOM file that was input.

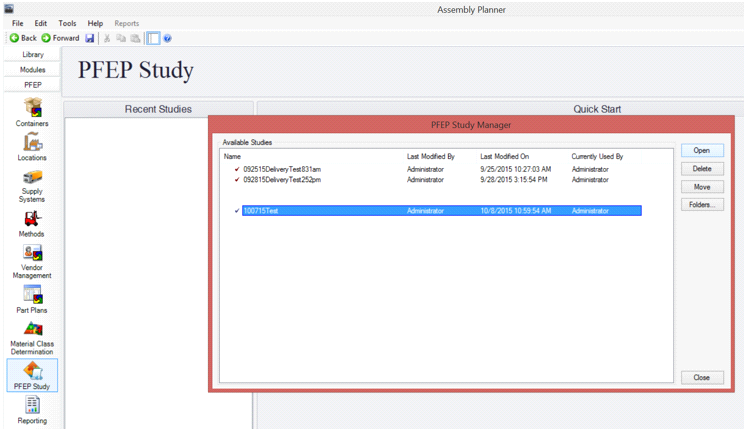

3.To open an existing PFEP study:

a.Click File > Open Study

b.Select the PFEP Study name and click Open.

3.Filter the BOM:

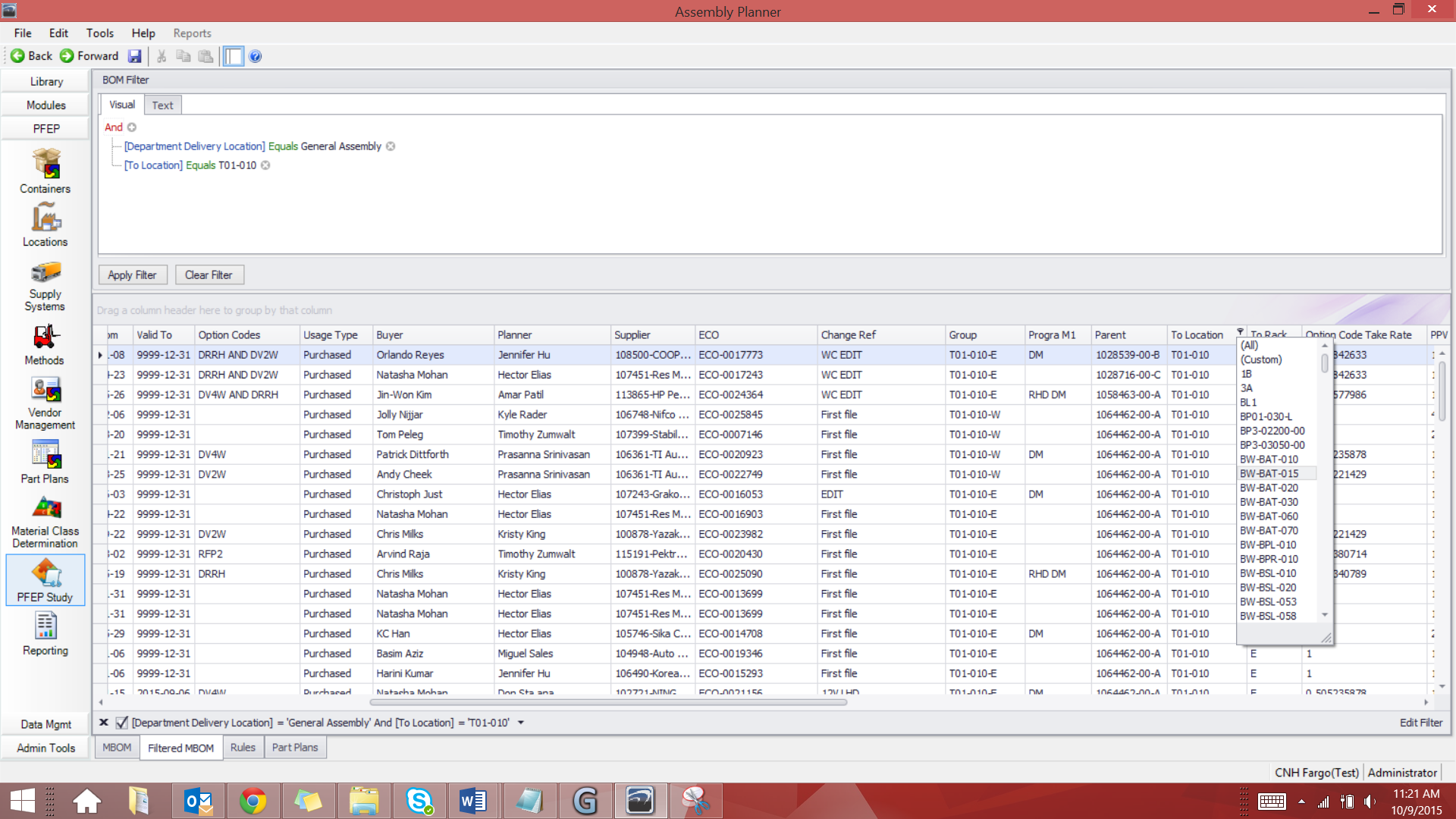

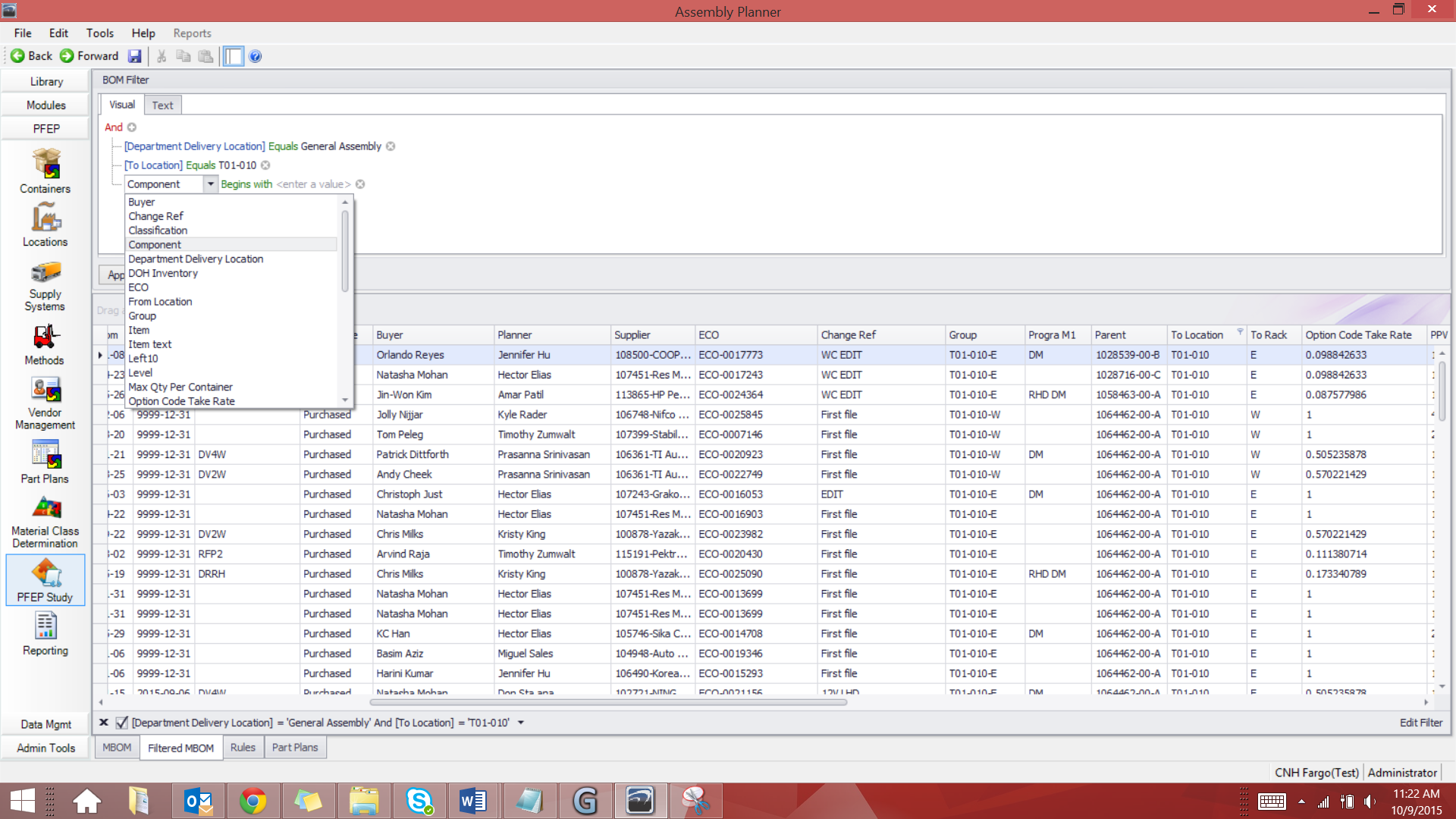

1.Click on the Filtered MBOM tab and use one of the following options to filter:

•Filter the MBOM by using the filter icon in the column header(s) and selecting the appropriate value.

•Filter the MBOM by clicking the Visual tab at the top.

i.Click and select the And/Or condition from the dropdown

ii.Click the Add symbol button

iii.Click and select the Column header name from the dropdown

iv.Click and select the appropriate Operator function from the dropdown

v.Entered the desired value(s)

vi.Click the Apply Filter button

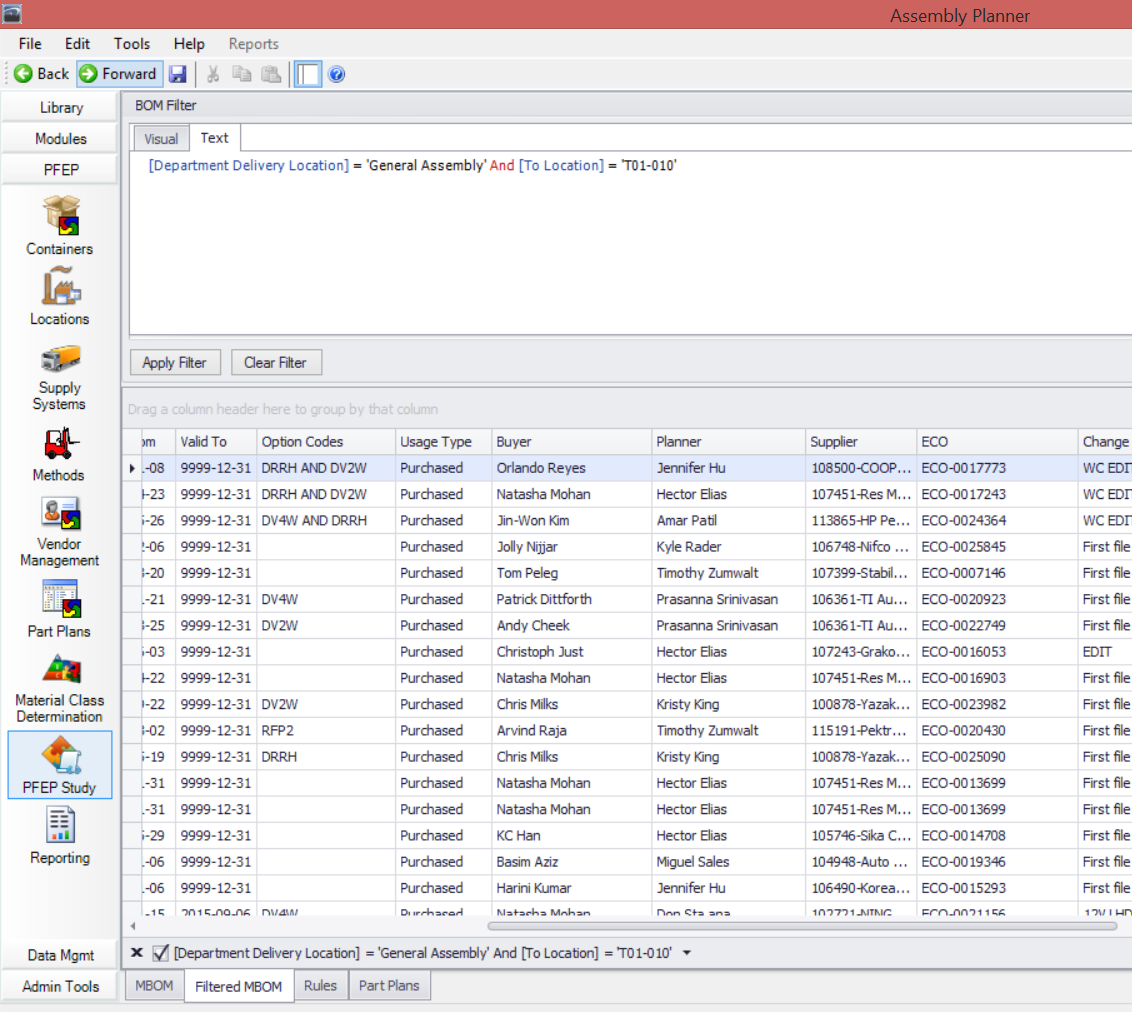

•Filter the MBOM by clicking the “Text” tab at the top.

i.Type the appropriate conditions, Column Header names, operators and values in the open Text field

ii.Click the Apply Filter button

*When filtering by any of the above options, the other options will auto-update so the filtering methods may be combined.

4.Apply Rules to Filtered BOM:

Rules can be defined that will populate any of the following part plan’s fields:

1.Intermediate Locations: set locations between the source and destination location.

2.Container and Parts per Container: Container ID and Parts per Container for moves between locations of the part plan.

3.Method of Delivery: Method name that will be used to move containers between locations of the part plan.

4.Process and Process Time: Process and time to perform process at To Locations of the part plan.

Fields that are used in Rule criteria:

1.Item() = Component or Item ID from BOM

2.Source() = Source Location ID from BOM

3.Dest() = Destination Location ID from BOM

4.From() = From Location ID

5.To() = To Location ID

6.P1C() = Primary Packaging Container ID

7.P2C() = Second Primary Packaging Container ID

8.SC() = Secondary Packaging Container ID

9.Cont() = Container ID from part plans

10.Class() = Classification column from BOM

Operators that can be used in Rule criteria:

1.AND, OR, NOT

2.Parentheses () to group criteria

3.“%” is multi-character replace

4.“_” is single character replace

Example:

NOT Source("%Small”) OR To(“%Station_0”)

From("%Stamp%") AND (NOT Dest("%Station%")) AND P1C(“BOX__0”)

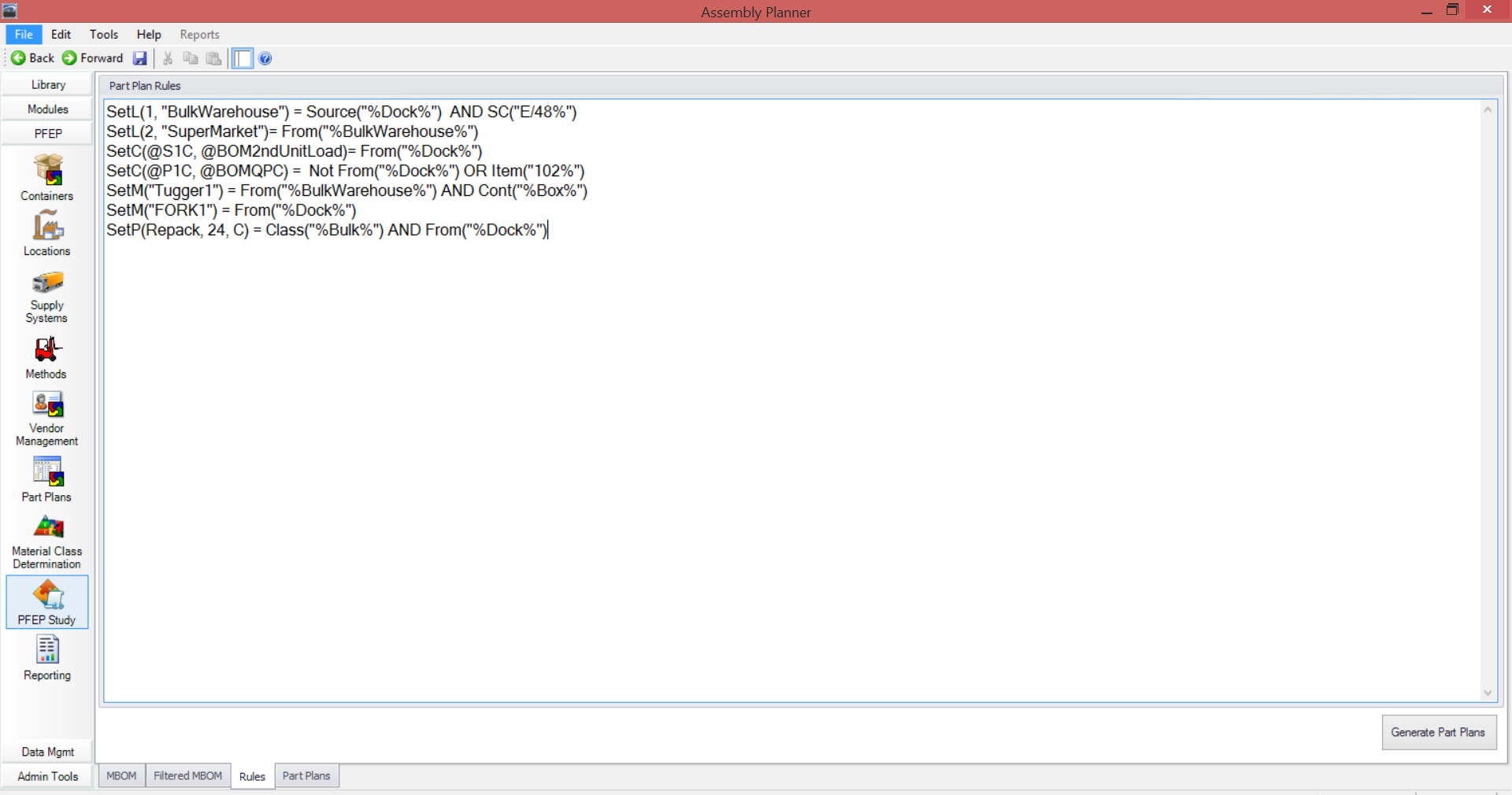

How to Create Rules:

1.Click on the Rules tab

2.Type in the appropriate rules using the following nomenclature for each rule:

a.Intermediate Locations:

SetL(Position n, Location ID) = Rule criteria

Rule Parameter # |

Format |

1 |

Any positive integer n denoting position in part plan to insert location |

2 |

Location ID. May be empty to indicate a null location. |

Examples: SetL(1, "Small Parts Store") = Item("%608") AND Source("%Small%") AND P1C("%Box%")

i.e.: Set Location 1 to “Small Parts Store” for all items that have an Item ID that ends with 608 and the item’s Source Location ID contains the word “Small” and the item’s Primary Packaging Container ID contains the word “Box”

SetL(2, "Supermarket") = Item("600%-0_-A") AND (Source("%Bulk%") OR Source("General%"))

b.Container and Parts per Container:

SetC(Container ID, quantity of parts per container) = Rule criteria

Rule Parameter # |

Format |

1 |

“Container ID” or @P1C or @P2C or @SC |

2 |

Quantity of parts per container (any non-negative number) or @BOMQty, @BOM2ndUnitLoad, or @ContQty – optional |

Examples: SetC(@P1C, @BOMQty) = NOT (Source("%Small%") AND To("%Store"))

i.e.: Set container to the Primary Packaging Container ID from the BOM and Quantity of Parts per container equal to the Max Qty per Container from the BOM for all items that do NOT have a combination of the Source location ID that contains the word “Small” and a To Location ID that ends in “Store”.

SetC("E/10.5x10.5x10.5/Corrugated Box", 20) = From("%Warehouse%")

SetC(@SC, @ContQty) = From("%Stamp%") AND Dest("%Station%")

c.Method of Delivery:

SetM(Method ID) = Rule criteria

Rule Parameter # |

Format |

1 |

“Method ID” |

Examples: SetM("FORK7") = From("%Small%") AND To("%Store") AND Cont("%Box%")

i.e.: Set delivery method to “FORK7”for all items that have a From location ID that contains the word “Small” and a To Location ID that ends in “Store” and a Container ID that contains the word “Box”.

d.Process and Process Time:

SetP(Process name, Process time, “P” or “C”) = Rule criteria

Rule Parameter # |

Format |

1 |

Process name |

2 |

Processing time (any non-negative number) – optional |

3 |

“P” or “C” |

Examples: SetP("Repack", 24, C) = From("%Warehouse%") AND (NOT To("%Store"))

i.e.: Set process to “Repack” at 24 seconds per container for all items that have a From location ID that contains the word “Warehouse” and a To Location ID that does not end with the word “Store”.

SetP("Repack", 12, P) = Item("600%-0_-A") AND From("%Bulk%") AND To("%market")

e.Set Entire Part Plan:

SetS(Location ID | Process name, time, P/C | Container ID, quantity per container | Method ID |..) = Rule criteria

Rule Parameter # |

Format |

1 |

Location ID |

2 |

Process name, time, “P or “C” – See SetProcess for details |

3 |

Container ID, quantity per container – See SetContainer for details |

4 |

Method ID |

Examples: SetS(@Source | "Repack", 24, C | "E/10.5x10.5x10.5/Corrugated Box", 20 | "TUG1" | "Small Parts Store" | | @P1C, @BOMQty | | "Supermarket" | "Repack", 12, P | @SC, @BOM2ndUnitLoad | "TUG1") = Item("600%-0_-A") AND Source("%Small%") AND (Dest("T%0") OR Dest("%BW%0"))

3.Click the Generate Part Plans button in the bottom right corner.

5.Review Part Plans Created:

6.Calculations for Reports:

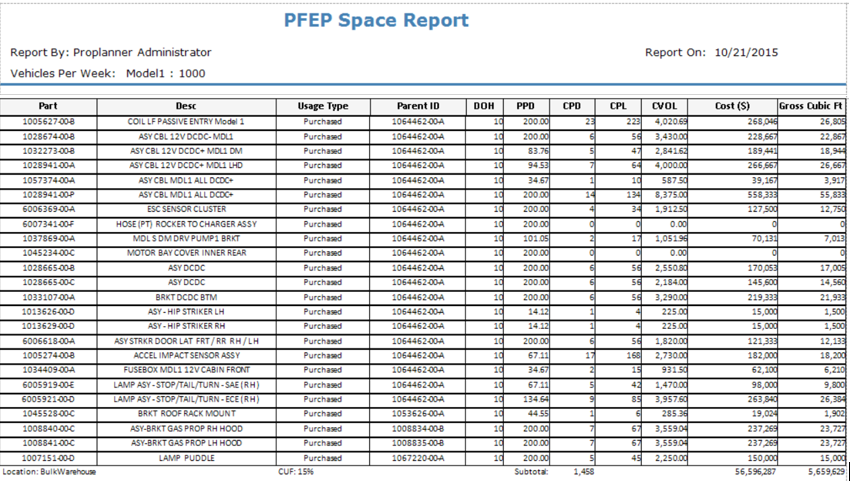

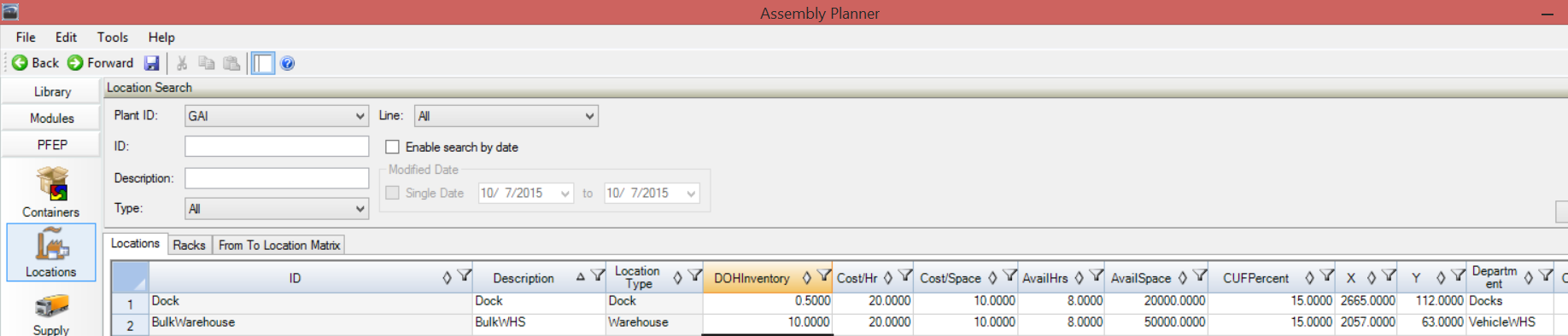

Space Report:

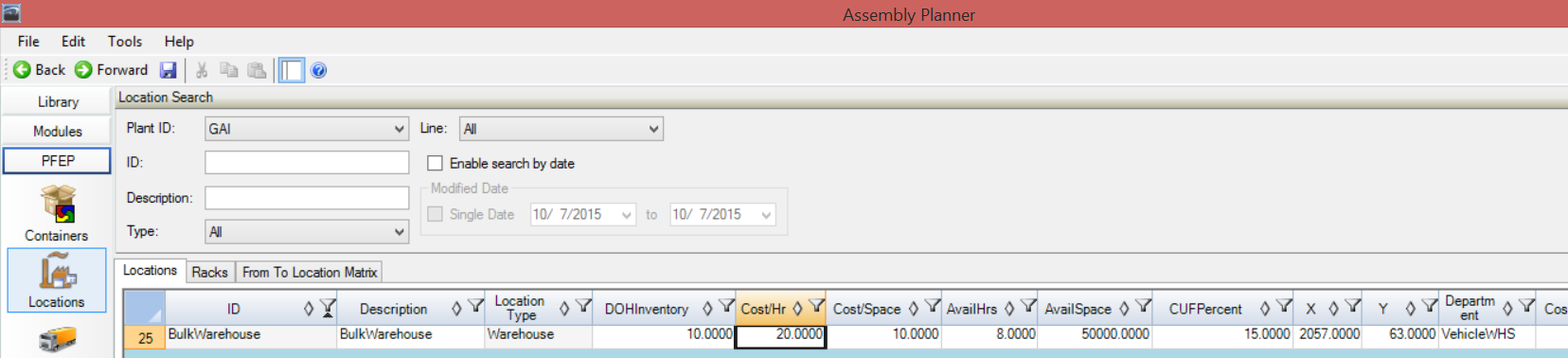

Location Details:

Report Output:

Report Calculations:

1.DOH (Days on Hand): Location table’s DOHInventory value is used first. If the Location table’s DOHInventory value does not exist, then the part DOH value is used.

2.PPD (Parts per Day): Parts per Vehicle (PPV) *Option Code Take Rate *(Vehicles per Week/5.)

3.CPD (Containers per Day): PPD/ Part Plan’s Density value (Qty per Container) and rounded up to the nearest whole container.

4.CPL (Containers by Location): PPD/ Part Plan’s Density value (Qty per Container) *DOH and rounded up to the nearest whole container.

5.CVOL (Container Volume by Location): (Container ID’s Length/12)*(Container ID’s Width/12)*(Container ID’s Height/12) rounded to nearest hundredth * CPL.

6.Cost: CVOL/ (Location table’s CUFPercent/100) * Location table’s Cost/Space and rounded up to the nearest whole dollar.

7.Gross Cubic Ft: CVOL/ (Location table’s CUFPercent/100) and rounded up to the nearest whole Cubic Ft.

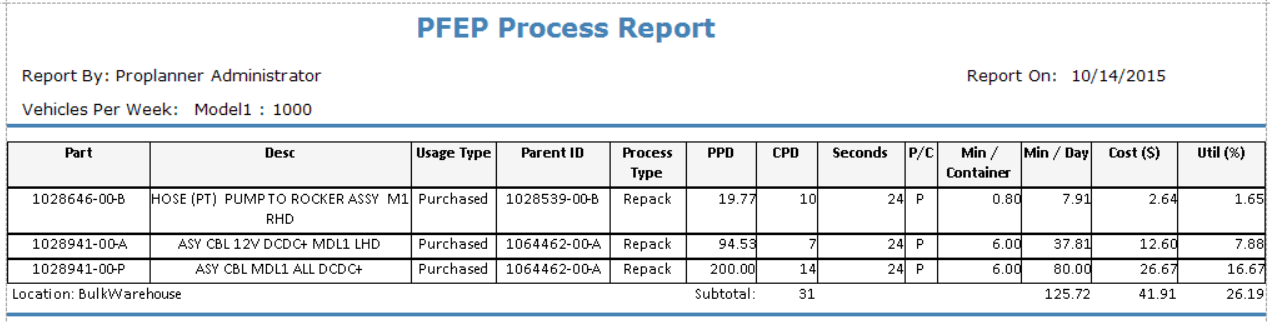

Process Report:

Location Details:

Report Output:

Report Calculations:

1.Process Type: Process Name.

2.PPD (Parts per Day): Parts per Vehicle (PPV) * Option Code Take Rate * (Vehicles per Week/5.)

3.CPD (Containers per Day): PPD / Part Plan’s Density value (Qty per Container) and rounded up to nearest whole container.

4.Seconds: Process Time from the Rules.

5.P/C: Pieces or Container. Determines how to multiply the Seconds column to calculate Min/Day.

6.Min/Container: If P/C = C, then Min/Container = Seconds / 60. If P/C = P, then Min/Container = Seconds * Part Plan’s Density value (Qty per Container) / 60.

7.Min/Day: If P/C = C, then Min/Day = PPD / Part Plan’s Density value (Qty per Container) * Seconds / 60. If P/C = P, then Min/Day = PPD / Part Plan’s Density value (Qty per Container) * Seconds * Part Plan’s Density value (Qty per Container) / 60.

8.Cost: Location table’s Cost/Hr * (Min/Day / 60).

9.Util (Utilization %): Min/Day / 60 / Location table’s AvailHrs * 100.

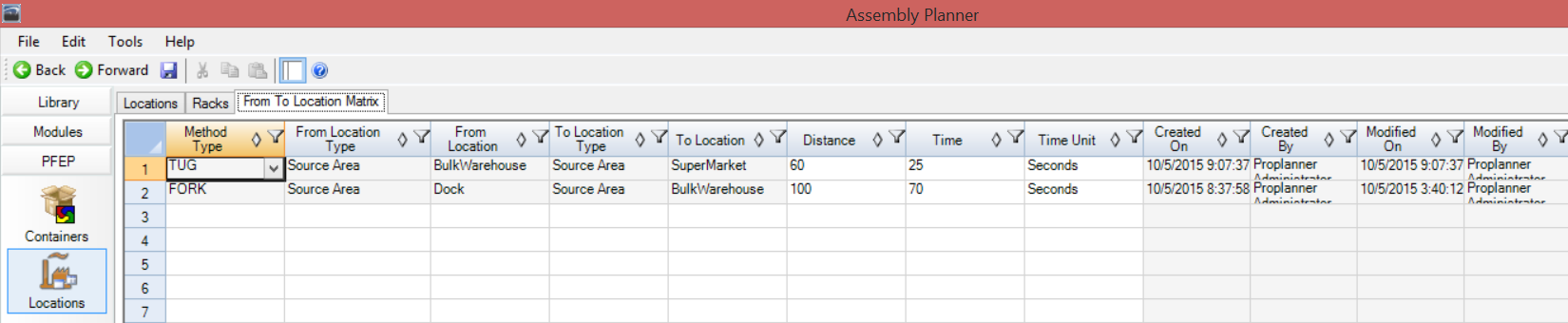

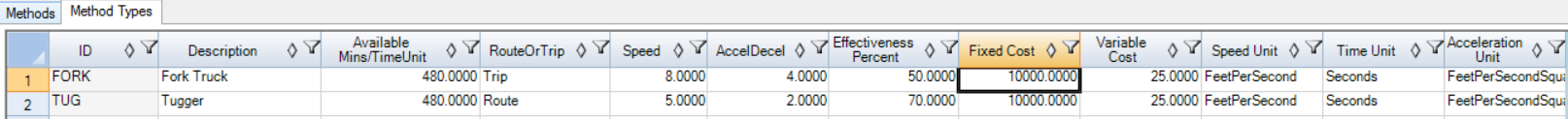

Trip Based Delivery Report:

Location Details:

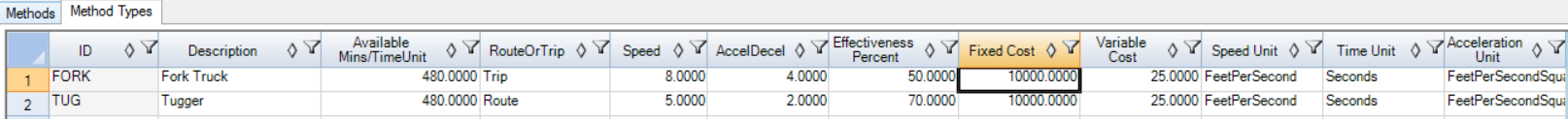

Method Details:

Report Output:

Report Calculations:

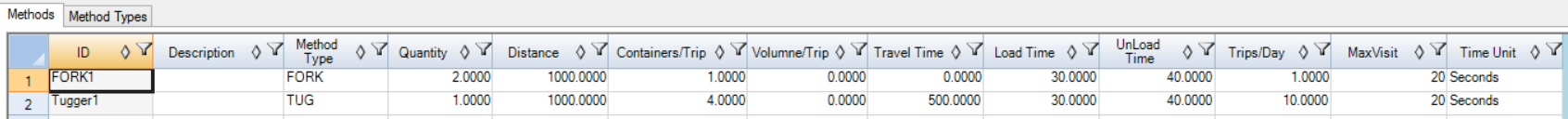

*Method Type’s RouteOrTrip must be set to “Trip” for the method to show on this report.

1.PPD (Parts per Day): Parts per Vehicle (PPV) * Option Code Take Rate * (Vehicles per Week/5.)

2.CPD (Containers per Day): PPD / Part Plan’s Density value (Qty per Container) and rounded up to nearest whole container.

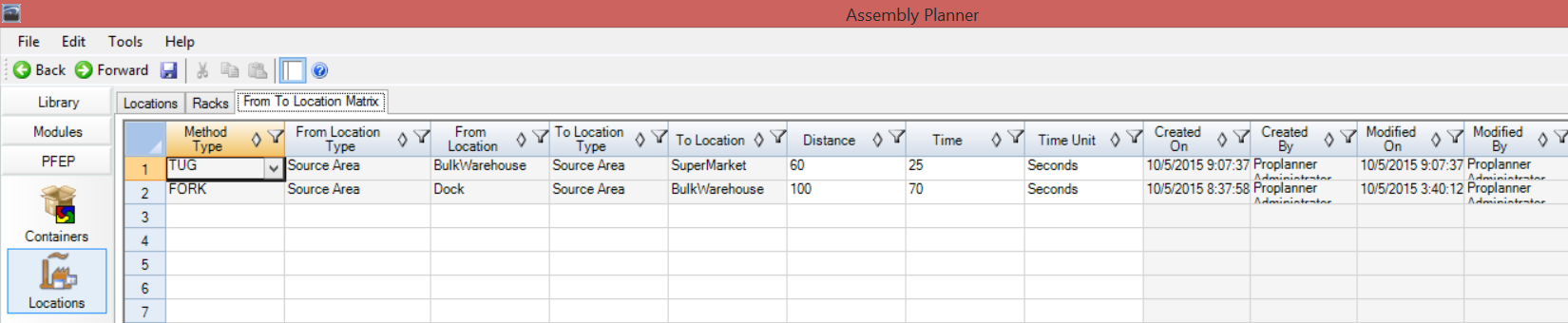

3.Per Trip Dist(ft): If the From Location, To Location and Method combination exists in the From-To Location Matrix in the Location table, then the Distance field is used. If not, then the rectilinear distance is computed using the From Location’s X and Y coordinates and the To Location’s X and Y coordinates in the Location table.

4.Per Trip Load + Unload (sec): Sum of the Load and UnLoad Time for the Method ID in the Methods table.

5.Per Trip Travel (sec): If the From Location, To Location and Method combination exists in the From-To Location Matrix, then the Time field is used. If the Time does not exist or the Time in the From-To Location Matrix is 0, then the time equals: Dist(ft) * Method Type’s Speed.

6.Per Day Time (min): (Load+Unload(sec) + Travel(sec)) * CPD / Method’s Containers/Trip / 60.

7.Per Day Eff Time (min): (Load+Unload(sec) + Travel(sec) / (Method Type’s Effectiveness Percent / 100)) * CPD / Method’s Containers/Trip / 60.

8.Subtotal(Method) Utilization %: SubTotal Eff Time(min) / (Method’s Quantity * Method Type’s Available Mins/TimeUnit) * 100.

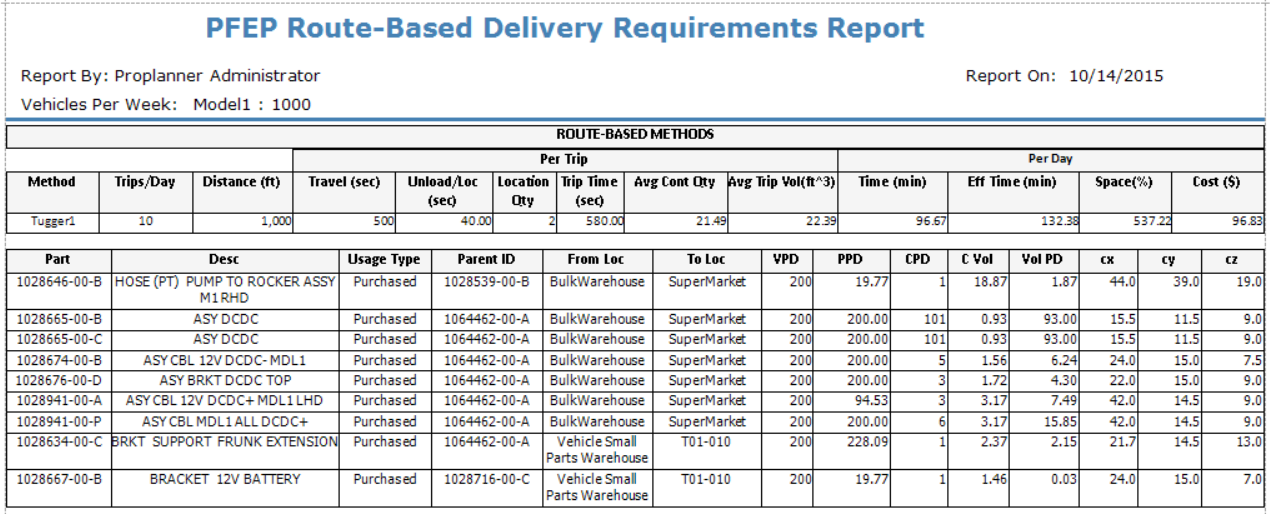

Route Based Delivery Report:

Location Details:

Method Details:

Report Output:

Report Calculations:

*Method Type’s RouteOrTrip must be set to “Route” for the method to be displayed on this report.

Route Method Summary Table Per Trip:

1.Trips/Day: Input from Methods table Trips/Day column.

2.Distance(ft): Input from Methods table Distance column.

3.Travel(sec): Input from Methods table Travel Time column.

4.Unload/Loc(sec): The UnLoad Time for the Method ID in the Methods table.

5.Location Qty: The number of each unique To Locations in Method Route.

6.Trip Time(sec): Travel(sec) + Unload/Loc(sec) * Location Qty.

7.Avg Cont Qty: Sum of all the part’s CPD / Method’s Trips/Day.

8.Avg Trip Vol(ft^3): Sum of all the part’s VolPD / Method’s Trips/Day.

Route Method Summary Table Per Day:

9.Time(min): (Travel(sec) + Unload/Loc(sec) * Location Qty) * Trips/Day / 60.

10.Eff Time(min): (Travel(sec)/ (Method Type’s Effectiveness Percent / 100) + Unload/Loc(sec) * Location Qty) * Trips/Day / 60.

11.Space%: If Method’s Volume/Trip = 0, then Space% = Avg Cont Qty / Method’s Containers/Trip * 100. If Method’s Volume/Trip <> 0, then Space% = Avg Trip Vol(ft^3) / Method’s Volume/Trip * 100.

12.Cost $: (Eff Time(min) / 60 * Method Type’s Variable Cost per Hour ) + (Method Type’s Fixed Cost * Method’s Quantity / 240 days per year.)

Route Method Detail Table:

13.VPD (Vehicles per Day): Vehicles per Week / 5.

14.PPD (Parts per Day): Parts per Vehicle (PPV) * Option Code Take Rate * (Vehicles per Week/5.)

15.CPD (Containers per Day): PPD / Part Plan’s Density value (Qty per Container) and rounded up to nearest whole container.

16.CVol (Container Volume): (Container ID’s Length/12)*(Container ID’s Width/12)*(Container ID’s Height/12).

17.VolPD (Volume per Day): CVol * CPD.

18.cx: Container ID’s Length from Container table.

19.cy: Container ID’s Width from Container table.

20.cz: Container ID’s Height from Container table.