The Plan for Every Part (PFEP) is a structure and concept within the Assembly Planner database that deals with the complete definition of in-plant logistics and storage for all parts from receiving to consumption. Every part has a logistics plan that connects Locations, Containers, Delivery Methods, Delivery Quantity, etc.

PFEP can be used on its own, simply as a record of all in-plant logistics data, but can also be used with two main transactional systems: eKanban and eKitting. eKanban is a materials replenishment method for small, low cost, bulk parts when containers become empty. eKitting is a system that deals with part picking and delivery of unit-specific parts in the sequence they are required to support the assembly line.

The database is also designed to export logistics data to Proplanner's Flow Planner application. This will allow evaluation of a plant layout and aisle networks to see how material flows throughout the plant.

Each section of PFEP is described in a subsequent section.

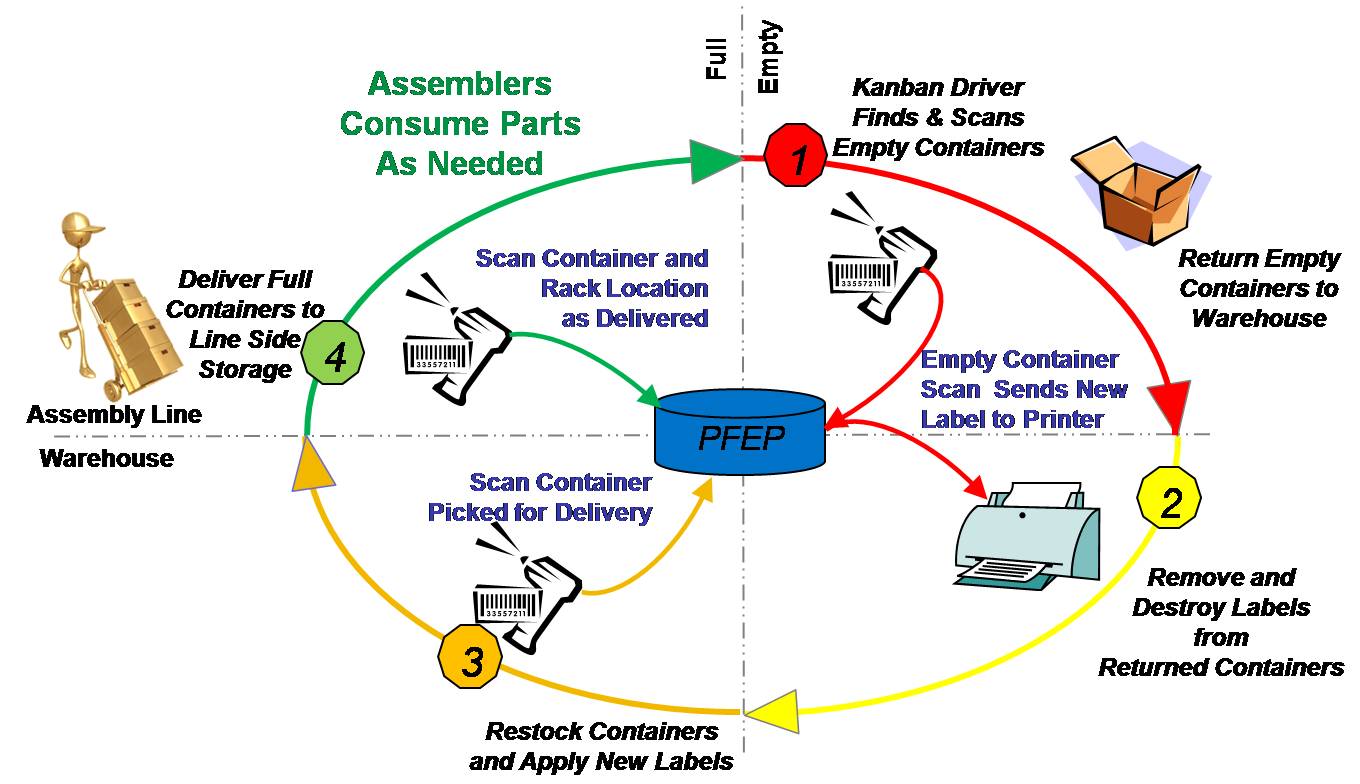

e-Kanban

The diagram below illustrates the workflow involved in using the PFEP e-Kanban system.

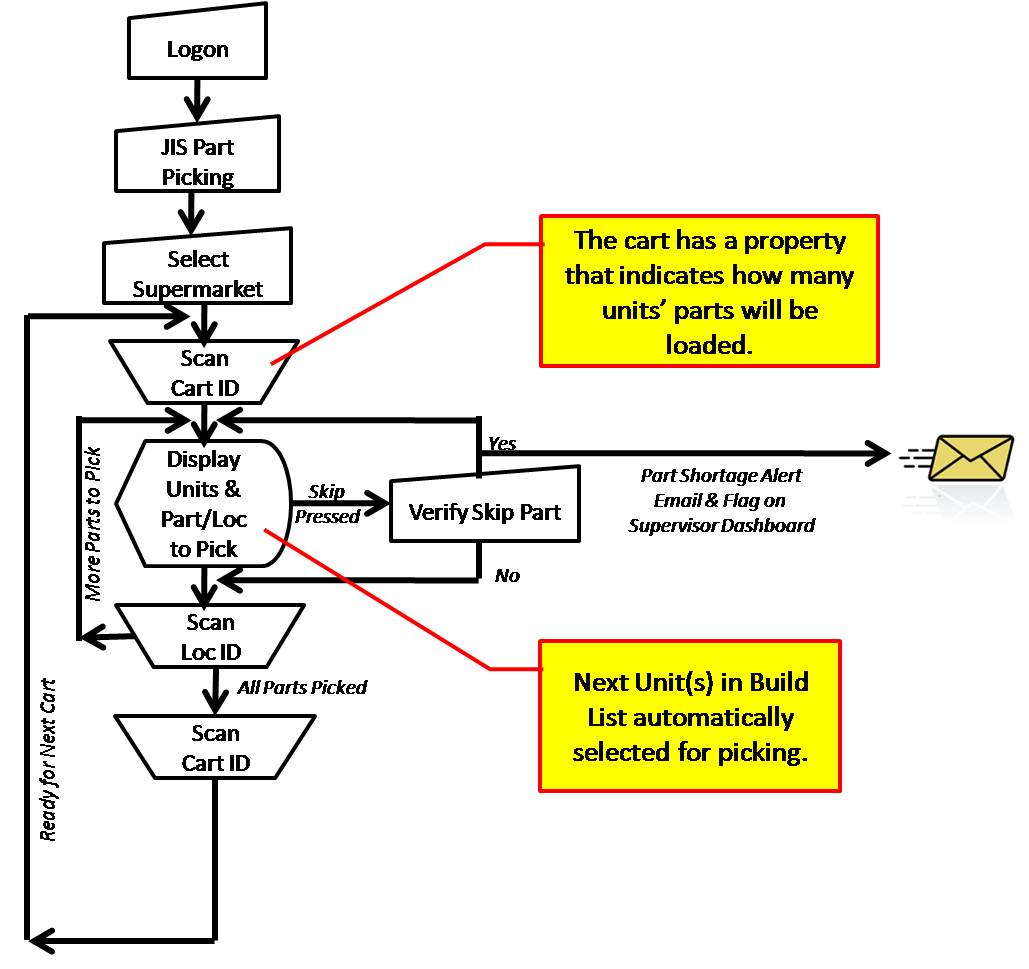

Just-in-Sequence Part Kitting

The diagram below shows the work flow for the Just-In-Sequence Part Kitting tool.