Process Failure Modes and Effects Analysis (PFMEA) is a tool that allows you to detect and prevent failures. PFMEAs can be performed for Routings, Operations, or Activities.

About PFMEA/Basic Structure

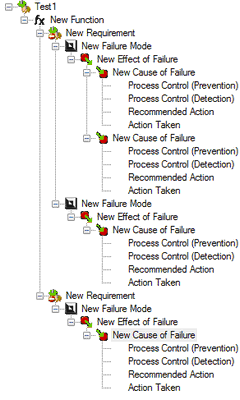

The basic structure for the PFMEA is described in the figure below. Remember that a PFMEA can have multiple functions, a function can have requirements, a requirement can have multiple failure modes, a failure mode can have multiple effects of failure, and an effect of failure can have multiple causes of failure. A PFMEA usually looks more like a branched tree than the graph of a linear equation.

PFMEA Tree

To begin the FMEA, a process is given a function. As an example, an activity 00000174 is to secure the seat of a chair to the base. The requirement for this function is that four bolts are used to secure it. Possible failure modes include using a gun with improper torque to tighten the bolts or using bolts with sub-standard material. Either of these modes may cause the back to fall off of the chair. The effect of failure is certainly customer dissatisfaction and possibly physical injury to the customer. The engineers of this chair determine that the ultimate causes of the failure are improper operator training and a poor inspection plan. Process control possibilities include enhanced operator and inspector training to prevent the failure, and a new test to detect faulty seat-back attachment to detect failure. The engineers recommend a plan to enhance operator training and new inspection policies. Both actions are being taken.

After performing a PFMEA, a Risk Priority Number (RPN) is generated, which helps you determine which issues need to be addressed first—higher RPNs are more important to address.

Assembly Planner calculates the Risk Priority Number with RPN = Severity x Occurrence x Detection. As the PFMEA is performed, you will assign

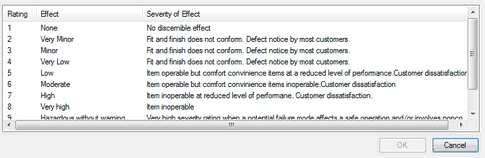

•a Severity value to each "Effect of Failure"

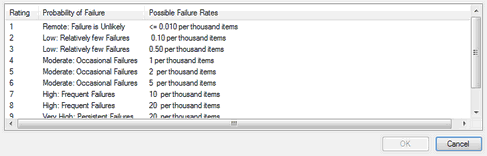

•an Occurrence value to each "Cause of Failure"

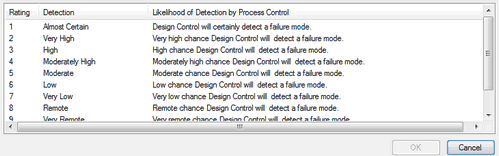

•a Detection value to each "Process Control"

RPN Calculator

Clicking the ![]() button after Severity, Occurrence, or Detection will bring up the respective standard set of values that Assembly Planner provides. Note that the values and buttons will not be able to be changed unless in Edit mode.

button after Severity, Occurrence, or Detection will bring up the respective standard set of values that Assembly Planner provides. Note that the values and buttons will not be able to be changed unless in Edit mode.

All three standard sets are shown below.

Severity

Occurrence (Probability of Failure)

Detection