The ProcessResource import allows you to map resources to activities. Doing an import allows you to bypass adding resources to the processes one-by-one.

Two options exist for the ProcessResource import: Add New or Merge.

•Selecting Add New will overwrite any existing resources mapped to the selected activities. The only resources that will be mapped to those activities are those included in the import file.

•Choosing Merge will add to or update current resource mapping. The resources in the import file will be added to the current resource mapping; if the activity already has a resource mapped to it and that resource is not included in the import file, the mapping of that resource will not be affected by the import.

There are certain fields that must appear in the spreadsheet file used to import resources. The table below lists the standard fields provided in Assembly Planner that are relevant to this import type. Each of these fields needs to be a column heading in the import spreadsheet file. The fields described as not mandatory do not need to be included as columns in the sheet.

In addition to the standard fields, the import file must also have a column that matches each user-created ProcessResourceMapping custom field to be imported.

ProcessResource Standard Fields

Field |

Description |

Mandatory to Import |

ResourceID |

The resource ID must be specified. The resource ID must already exist in the resource library; you may only map resources that have already been imported or otherwise added before doing a process-resource import. |

Yes |

OperationSeqNo |

The Operation Sequence Number (OpSeqNo) of the operation to which the resource mapping applies. |

Yes |

OperationEffectiveFromDate |

The Effective From Date of the operation. It is not mandatory to make an entry in this column. May be useful in cases where there are multiple operations with the same OpSeqNo that have different effectivity dates. |

Yes |

OperationEffectiveToDate |

The Effective To Date of the operation. It is not mandatory to make an entry in this column. May be useful in cases where there are multiple operations with the same OpSeqNo that have different effectivity dates. |

Yes |

ActivitySeqNo |

The Activity Sequence Number (ActSeqNo) of the activity (under the specified OpSeqNo) to which the resource mapping applies. Either the ActSeqNo or the ActivityID is required. |

Yes* |

ActivityID |

The Activity ID of the activity (under the specified OpSeqNo) to which the resource mapping applies. Either the ActSeqNo or the ActivityID is required. |

Yes* |

ActivityEffectiveFromDate |

The Effective From Date of the activity. It is not mandatory to make an entry in this column. May be useful in cases where there are multiple activities with the same ActSeqNo that have different effectivity dates. |

Yes |

ActivityEffectiveToDate |

The Effective To Date of the activity. It is not mandatory to make an entry in this column. May be useful in cases where there are multiple activities with the same ActSeqNo that have different effectivity dates. |

Yes |

Quantity |

The quantity of the resource required for the process. For example, if two torque guns are required, enter a '2' in this column. |

No |

RoutingID |

The process is added to the Routing that is specified in RoutingID |

Yes |

RoutingType |

Routing Type is valid only for a Routing. For activities, do not provide a value here. Users typically create routings with a Routing Type of ‘M’. However, other values (such as A) will be valid as well. The list of available Routing Types may have to be configured for different clients.

If left blank, will default to M. |

Yes |

PlantID |

The process is added to the plant whose ID is specified. Many users only have one plant set up in their Assembly Planner system; if you are unsure as to the ID, check in the Library > Plant Tab. |

Yes |

*Either the ActSeqNo OR the ActivityID is required for the import. You only need one of the two; you are allowed to use both.

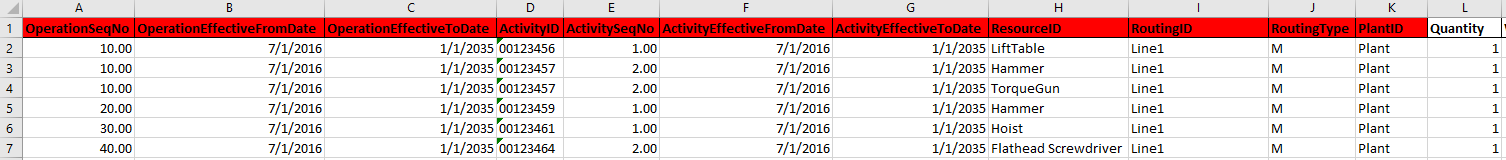

Example Process Resource Import Spreadsheet

*Note - Red Headers have to be filled in for import to work correctly.