The concept of models and options is an integral part of Assembly Planner, because Models and Options are an integral part in the sale and production of most of our clients' complex assembly products. Models typically represent high level types of products (sometimes referred to as families), while options represent features applied to those models to allow for further variation and customization. Different product models and options require different assembly processes. Some processes may be performed on multiple models and/or options, while other processes may be unique to just one or two models and/or options. If this information is specified, Assembly Planner can help create work instructions specific to each model + options configuration, display accurate mixed model line balances, and more.

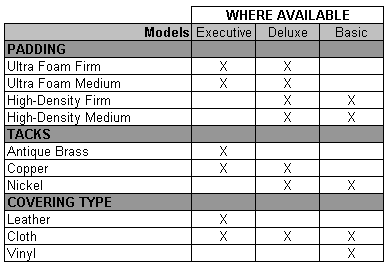

The Model and Options Editors are where models and options are created and managed in Assembly Planner. The simple chair example below can be used to explain how the Model and Option Editors work in Assembly Planner. Models represent the different types of chairs: executive, deluxe, and basic. Of course, there are options within the models; not all executive chairs look exactly alike (nor are they priced or made in exactly the same way). A customer could purchase an executive chair that has a cloth covering on the seat and back secured with copper tacks. Or the customer could decide to upgrade to the leather covering and the antique brass tacks. In Assembly Planner, each individual option can fall into an option group. In this example, the groups are padding, tacks, and covering type. The table below shows the different models and options as well as the model-option configurations, or, how the models and options can be combined.

Model Option Configuration

More information on setting up Option groups is included in the Option Editor section.