Clicking the MCO button ![]() will open the MCO Editor.

will open the MCO Editor.

The Manufacturing Change Order, or MCO, is used to indicate pending engineering changes to the process engineers. The ECR and ECO indicate to the engineer which portions of a Bill of Materials are changing, because the engineer needs to evaluate and update processes accordingly.

An MCO is created once the engineering change (either an ECR or ECO) is assigned to a user.

When searching for MCOs in the MCO List, they will be arranged by categories in order of earliest to latest due dates.

MCO Header

The MCO Header contains summary information. The fields include:

•MCO No: The MCO is generated automatically at the time the ECR or ECO is assigned.

•Status: This indicates the level of processing completed on the MCO.

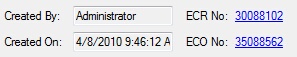

•Created By: The ID of the MCO Coordinator or Administrator that assigned the ECR or ECO, creating the MCO.

•Created On: The date the MCO was created.

•ECR No: The identification number of the ECR corresponding to this MCO. This field contains a hyperlink to the ECR.

•ECO No: The identification number of the ECO corresponding to this MCO. This field contains a hyperlink to the ECO.

If the corresponding ECO has not yet been received, only the ECR number is displayed.

If there is an ECR-ECO mismatch (in which case only the ECO is processed), only the ECO number is displayed.

ECR and ECO number

•Project No: The project number, as listed in the header file from the engineering system.

•Released On: The date the MCO was created.

•Due Date: The date by which the MCO must be processed.

•Priority: This field is set when the ECR or ECO is assigned. Possible values include Routine, Important, High Priority, and Emergency.

•Default From Effectivity Date: This is the default date on which the items in the MCO will become effective. This sets all items to the same time-in date at the creation of the MCO. The default date can be overwritten, and individual Effective From dates assigned to any of the items.

•Reason: This text field that can be used to record the reason for the changes described in the MCO. The field can be changed by an MCO Coordinator, an administrator, or the engineer to which the MCO is assigned.

•Description: This text field that can be used to record a description of the changes in the MCO. The field can be changed by an MCO Coordinator, an administrator, or the engineer to which the MCO is assigned.

The action buttons that appear in the MCO header area allow the engineer to process the MCO. The possible actions are:

•Cancel MCO: This will cancel the MCO, rolling back any changes made to a component or BOM affected by the MCO. Any MCO that has not yet reached the implement state may be canceled.

To cancel an MCO, select it from the list. Click the 'Cancel MCO' button. You will be asked to confirm the action; select 'Yes'.

•Re-Assign: This allows the MCO to be assigned to a different engineer. This feature is helpful if the MCO Coordinator does not initially know which engineer will ultimately be responsible for a change; it allows the Coordinator to assign the MCO temporarily and reassign it later.

To reassign an MCO, select the MCO on the list. Then click the Re-Assign button; you will be asked if you are sure you want to reassign the MCO. When you choose 'Yes', a drop-down list will appear and you will be able to select the user to whom the MCO should be assigned. Click 'OK' to assign the MCO.

•Promote: This is how MCOs are processed through the system. The engineer responsible for the MCO should be changing the status as the plant works through different stages.

When the MCO is created, it is in the Process state.

The Approve state is intended for MCOs where the ECO has not been received, but the plant is reviewing the ECR.

After the ECO arrives, an MCO should move to the Release state; this will change the eBOM status for all affected components to 'Released'.

After the ECO changes have been implemented in the plant, the MCO can be moved to Implement. The status of the mBOM will be changed, and any exports to the MRP system will be exported.

Verify and Complete are both states that deal with post-implementation analysis.

For more information, see the MCO Status section.

•Demote: The Demote function allows an MCO to be moved back to a different state (e.g. from Release back to Approve). You may not demote an MCO after it has reached the implement state.

•Update: This will save any changes made to the MCO or MCO Custom Fields.

MCO Tabs

The Custom Fields Tab displays all extra information associated with the MCO. If you change the values of any of these fields, remember to use the Update button to save the changes.

The Documents Tab contains a list of all of the documents associated with this MCO.